By Chuck Petersen

Even though the winter of 2000/2001 was about average for our area, the extremely mild conditions of the past two years made this season seem long indeed! While ice still grips our lake in Southern Wisconsin, the first 50 degree days get the blood going as thoughts pass from snowmobile rides to boating. Is your outboard ready? I have found that a little attention to detail now can help prevent down time in July.

Three main areas need attention:

First, the lower unit or gearcase should have fresh gear lube. I change this every fall to rid the system of water and/or deposits gathered during the summer season. This is a must if the motor is to be stored in an unheated environment. I use Mercury Quicksilver High Performance oil. It costs a little more, smells really bad, but is worth every penny. In addition, replace the drain plugs and vent screw gaskets regularly. They are readily available in after market and are cheap insurance against leakage. Remove prop and grease shaft with anti-corrosion type water-proof grease every year. Inspect prop for damage to internal rubber hub or shear pin if so equipped. If the prop nut and/or washers seem worn, replace them.

First, the lower unit or gearcase should have fresh gear lube. I change this every fall to rid the system of water and/or deposits gathered during the summer season. This is a must if the motor is to be stored in an unheated environment. I use Mercury Quicksilver High Performance oil. It costs a little more, smells really bad, but is worth every penny. In addition, replace the drain plugs and vent screw gaskets regularly. They are readily available in after market and are cheap insurance against leakage. Remove prop and grease shaft with anti-corrosion type water-proof grease every year. Inspect prop for damage to internal rubber hub or shear pin if so equipped. If the prop nut and/or washers seem worn, replace them.

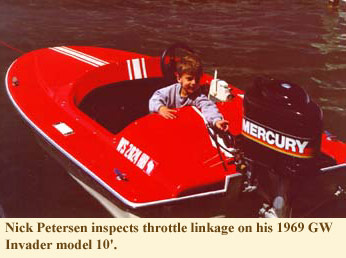

Second, grease all tower housing fittings, throttle linkage and steering linkage. Check co-pilot integrity on tiller models. Be sure throttle cables operate freely before motor is remounted to hull.

Finally, to the powerhead. Clean all exterior surfaces. If equipped with recoil starter, check for wear to mechanism and rope. Replace starter rope if even slightly worn! With last seasons spark plugs installed start and run motor in test tank or with fresh water ear muffs to clear excess storage oil. Replace plugs every season. I like NGK brand if available for your model. I spent my first serious hours on a snowmobile this past season. They seem prone to fouling plugs as spares are standard equipment. All major snowmobile lines use NGK plugs exclusively. Inspect and wipe wires and boots with silicone spray. Formula 2001 works well here. Clean and/or replace fuel filter if so equipped. I use a separate water-separating unit mounted to the boat transom between the fuel tank and the motor. Finally, never, ever use RFG (reformulated gas) if prevalent in your area. The lakeshore counties around Milwaukee and Chicago mandate this junk and I avoid it at all costs. Fortunately, our lake is far enough inland to get decent gas. Racers actually transport their own gas to avoid bad surprises using local brew.

Finally, to the powerhead. Clean all exterior surfaces. If equipped with recoil starter, check for wear to mechanism and rope. Replace starter rope if even slightly worn! With last seasons spark plugs installed start and run motor in test tank or with fresh water ear muffs to clear excess storage oil. Replace plugs every season. I like NGK brand if available for your model. I spent my first serious hours on a snowmobile this past season. They seem prone to fouling plugs as spares are standard equipment. All major snowmobile lines use NGK plugs exclusively. Inspect and wipe wires and boots with silicone spray. Formula 2001 works well here. Clean and/or replace fuel filter if so equipped. I use a separate water-separating unit mounted to the boat transom between the fuel tank and the motor. Finally, never, ever use RFG (reformulated gas) if prevalent in your area. The lakeshore counties around Milwaukee and Chicago mandate this junk and I avoid it at all costs. Fortunately, our lake is far enough inland to get decent gas. Racers actually transport their own gas to avoid bad surprises using local brew.

If you are like me, the outsides are important too! Wax painted cowlings with a high quality brand. If mineral deposits have formed around exhaust areas, Lime Away product works well to clean deposits prior to waxing. I really enjoy spending an afternoon in the sun getting my boat/motor ready for service. Dont skimp on the details!!

I hope to see you at the Rendezvous this summer!